Turbine material details

The

Turbine is operated in hi temperature, pressure ,speed and erosion environment.

So materials need are for Cr, Ni and Mo, V-based alloys for operation at 537 to

600°C with (i) adequate creep rupture strength; (ii) ability to cast them into

the required size and shape, and to inspect for defects; and (iii) ability to

perform initial fabrication welding (on cast or wrought forms, including

dissimilar metal welds), and to make repair welds on aged material. It is

observed that percentage of Cr and Ni are increased to improve the quality of

steel for the different parts of the turbine.

|

Component |

566°C |

620°C |

700°C |

760°C |

|

Casings/Shells |

CrMoV

(cast) |

9-10%Cr(W) |

CF8C-Plus |

CCA617 |

|

(valves;

steam |

10CrMoVNb |

12CrW(Co) |

CCA617 |

Inconel

740 |

|

chests;

nozzle box; |

CrMoWVNbN |

Inconel

625 |

CF8C-Plus

(?) |

|

|

cylinders) |

IN

718 Nimonic 263 |

|||

|

Bolting |

422 |

9-12%CrMoV |

Nimonic

105 |

U700 |

|

9-12%CrMoV |

A286 |

Nimonic

115 |

U710 |

|

|

Nimonic

80A |

IN718 |

Waspaloy |

U720 |

|

|

IN718 |

IN718

Allvac718Plus |

Nimonic

105 Nimonic 115 |

||

|

Rotors/Discs |

1CrMoV |

9-12%CrWCo |

CCA617 |

CCA617 |

|

12CrMoVNbN |

12CrMoWVNbN |

Inconel

625 |

Inconel

740 |

|

|

26NiCrMoV115 |

Haynes

230 Inconel 740 |

|||

|

Vanes/Blades |

422 |

9-12%CrWCo |

Wrought

Ni- |

Wrought

Ni- |

|

10CrMoVNbN |

base |

base |

||

|

Piping |

P22 |

P92 |

CCA617 |

Inconel

740 |

Material for casing has complex structure

, It should have been hi steam oxidation resistance, castability or forged still

be heat-treated and tempered to produce the best combination of high

temperature strength and ductile-to-brittle transition temperature (DBTT) behaviour

at low temperature.

The choice of blading material will

depend on (i) the-temperature-of-the rotor, hence on the thermal expansion

characteristics of the component material, and (ii) the size and shape of the

blade, which will be designed using computational fluid dynamics modeling.

The main issues for rotors/discs

concern manufacturing, especially the capability to produce large castings and

forgings. With modern secondary steel making practices, such as ladle furnaces,

electroslag remelting to control freezing segregation, and control of the

sulfur and phosphorus levels in the alloy, very large rotors now can be

produced, but experience is related mostly to Cr-Mo-V alloys (used in current

541-566°C plants), and for 12 Cr alloys (needed for advanced steam cycles to

620°C).

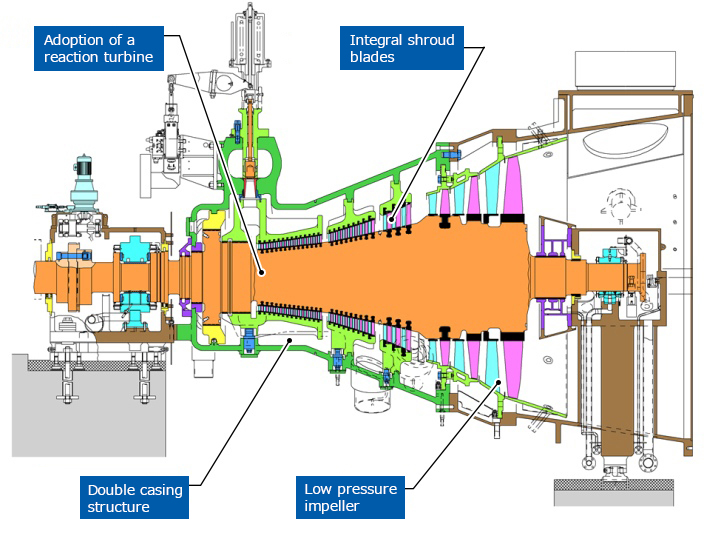

This is the material plan for different

parts of the turbine for super critical steam turbine HP and IP section.

Usage of higher grade of steel for 700-760degC and design data points are not available. Major issues are forging and casting procedure, weldability and costing of the materials and manufacturing.

Comments

Post a Comment

If you any doubt please send me mail on snehamaity@yahoo.co.in